U.S. Manufacturing Growth & Outlook in 2021

Posted on March 17, 2021

Manufacturing has been a core aspect of the U.S. economy since the late 1700’s, but the future of manufacturing may be turbulent. After a disruptive 2020, employers are anticipating a return to relative normalcy and growth in the manufacturing sector.

The global pandemic sent a shockwave through the U.S. manufacturing, with disruptions in international supply chains, quarantine and lockdown orders, diminished demand for certain goods, and more. Before the pandemic, a skills gap had manufacturing jobs in relatively high demand, with millions of unfilled positions ready for specialized workers. Employers, workers, and HR professionals are adapting to the challenges presented by the pandemic, and 2021 could prove to be a fruitful year for innovators in the manufacturing sector.

COVID-19 & U.S. Manufacturing

The global COVID-19 pandemic has affected U.S. manufacturers across the economy. Some industries saw an increase in demand (medical devices, streaming technology, home workout equipment) while others (aviation, business apparel, fossil fuels, travel industry) faltered. Small businesses took a disproportionate hit, as the U.S. Census Small Business Pulse Survey found 50% of businesses reported a “large negative effect from the COVID‐19 pandemic” and that a minority of small businesses (15%–20%) have enough capital to cover three months of operations.

Manufacturers and economists predict some lasting and foundational changes beyond the pandemic. Some anticipate more reliance on localized U.S. manufacturers and reduced demand for globalization. Though this is a promising development for many U.S. manufacturers that could see a spike in demand, many concerns remain.

According to PwC, American manufacturers have several pressing concerns regarding the post-pandemic economy:

Since before the Industrial Revolution, manufacturing has steadily evolved as new technologies develop. The first automatic flour mill was built in 1785, and since then, the production of goods has become a significant part of the American economy. US manufacturing growth has been a priority for working Americans, politicians, employers, and the global economy.

Today’s manufacturing employees work alongside automated equipment and computer-controlled machines. In recent years, a skills gap has put manufacturing jobs in high demand, with millions of unfilled positions ready for specialized workers.

Here, we take a look at the evolution of American manufacturing, an industry that has become an important talking point in politics and beyond. Get data and insights into American manufacturing’s past and present that will inform the future of this vital American industry.

How Manufacturing Has Evolved to Present Day

A common first thought about manufacturing is an assembly line: parts and products moving down a conveyor belt that rely on human labor for production. The Bureau of Labor Statistics reveals the diversity of manufacturing, spanning sub-sectors such as:

- Apparel manufacturing

- Food manufacturing

- Chemical manufacturing

- Machinery manufacturing

- Furniture and related product manufacturing

- Transportation equipment manufacturing

How U.S. Manufacturing Has Changed

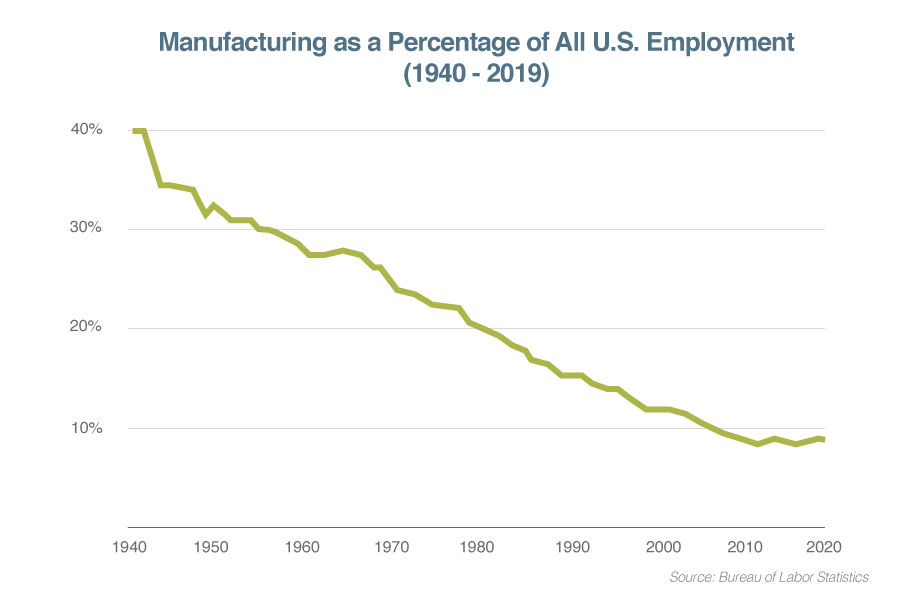

Since the 1950s, numeric and scientific computer programs developed. The first industrial robots entered manufacturing plants in the 1970s. In 1979, the American manufacturing employment rate reached its peak.

Since U.S. manufacturing reached its employment peak in 1979, there has been a decisive focus on efficiency. Systems like Six Sigma improve quality and minimize errors, while Computer-Integrated Manufacturing (CIM), robotics technology, and automation has developed rapidly. 3D printing, which first originated in the 1980s, is now widely used for a variety of products, including artwork. As a result, manufacturing employment has drastically decreased, particularly between 2000 and 2010, FRED Economic Data shows. Since then, manufacturing employment in the U.S. has seen an uptick, even despite the disruptions of the pandemic.

To take advantage of the market, today’s workers must adjust to disruptive technologies in the manufacturing space. Tools like advanced robotics, Big Data and the Internet of Things, as well as processes including additive manufacturing and 3D printing, are shaping today’s manufacturers.

Workers with the skill to work with these technologies will contribute to the advancement of American manufacturing. In 2018, over one year, the U.S. manufacturing industry added 327,000 jobs, which CNBC reports is the most of any 12-month period since 1995.

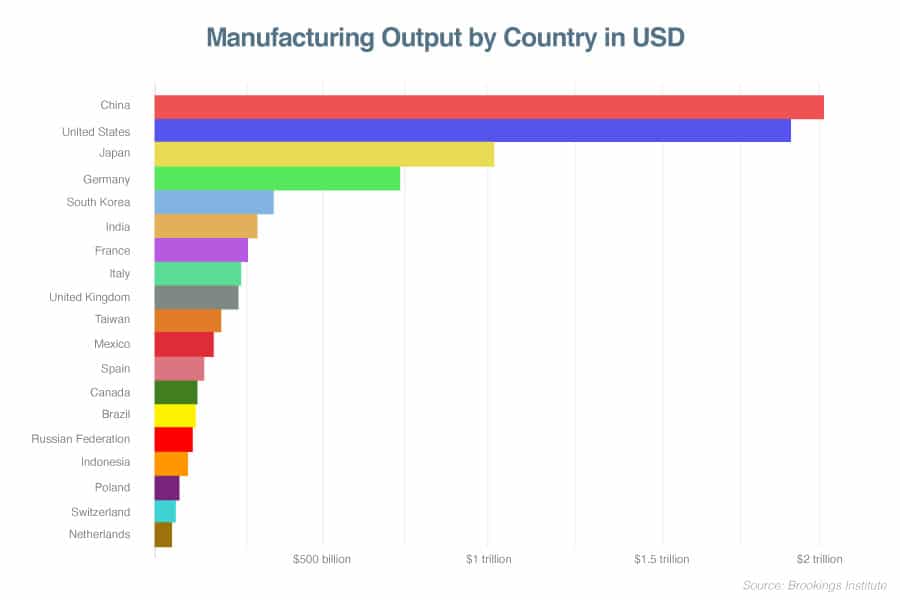

As the cost of technology like industrial robots falls, manufacturing employees can benefit. While American labor costs are significantly higher compared to countries like China, India, and Mexico, American manufacturing productivity makes up for the difference, according to a 2018 report by the Brookings Institution. Gaps in labor costs are decreasing. High productivity makes America an attractive location for manufacturing investment.

The State of American Manufacturing in 2021

Despite the temporary setbacks caused by the COVID-19 pandemic, the Brookings Institution report found potential for a resurgence in demand for U.S. manufacturing, due to factors like:

- A strengthening economy

- Workforce quality

- Tax policies

- The regulatory environment

- Transportation and energy costs

The report includes an analysis of data on 20 indicators, scoring 19 leading nations from North America, South America, Europe and Asia. The United States was the third top-ranked nation in overall manufacturing environment, only one point behind both the United Kingdom and Switzerland. The report found these three nations performed well due to workforce investments, policies, considerations and infrastructure.

According to a 2019 report by The Balance, U.S. manufacturing production is the largest around the globe, responsible for producing 18.2% of the world’s goods. China, the second-highest manufacturing producer, produces 17.6%.

In 2018, the gross domestic product (GDP) from manufacturing was $2.33 trillion, driving 11.6% of U.S. economic output. Manufactured goods make up half of American exports.

Download our eBook: Everything You Need to Know About Manufacturing Staffing

Discover the historical context, recent data, and best practices for staffing manufacturing jobs in America. Download our eBook, “Everything You Need to Know About Manufacturing Staffing” for data-driven strategies for staffing manufacturing jobs.

There are 12.85 million manufacturing jobs that employ 8.5% of the American workforce. On average, manufacturing jobs pay 12% more than jobs in other industries.

American manufacturing drives the U.S. economy in other ways. Every dollar that is spent in manufacturing contributes $1.89 in business growth in supporting industries like business services, transportation and retailing, The Balance reports. According to the Brookings Institution, American manufacturing drives 35% of productivity growth and 70% of private sector research and development.

In September 2019, the Bureau of Labor Statistics (BLS) reported that there were 469,000 job openings in manufacturing and 362,000 new hires in the industry. The BLS reports while 7.5 million jobs in manufacturing have been lost since 1980, job opening rates in manufacturing have nearly doubled in the 2000s. In 2001, they were at 1.8%, and in 2017, they were at 3.1%.

Workers with degrees, certifications and higher skill levels are more likely to be sought out in manufacturing, for positions such as software developers, computer programmers and engineers.

Reasons for a Decline in Manufacturing

To make strides in the manufacturing industry, it’s important to acknowledge reasons behind its overall declining workforce in the U.S. since the 1980s. According to the 2018 report “The transformation of manufacturing and the decline of U.S. employment,” the following reasons have contributed to a decline.

- Rising trade with China, which accounted for about a fourth of the decline in manufacturing jobs in the 2000s

- Supply chain disruptions due to COVID-19

- Decline in cross-regional migration

- Skills mismatch, which is the gap between the skills workers have and the skills employers need

According to the 2018 Deloitte and the Manufacturing Institute skills gap and future of work study, a shift to a service-based economy, including financial and banking services, as well as an increased demand in the healthcare sector are also contributing to manufacturing’s decline. The Deloitte report also mentions the high standard of living in the U.S. that still currently make labor costs much greater compared to other countries.

Also, Deloitte reports 89% of executives agreed there was a talent shortage in the American manufacturing industry. This is 5% higher compared to 2015 results. Between 2018 and 2028, the skills gap could leave 2.4 million jobs unfilled, which would cost the industry $454 billion in 2028.

Signs Pointing to Manufacturing Growth

Despite these factors, the outlook for manufacturing is looking bright. The Manufacturers Alliance for Productivity and Innovation Foundation predicts a 3.9% growth in production for 2019, then 2.4% in 2020 and 1.9% in 2021. Manufacturing is forecast to increase faster than the general economy, due to more exports and increased capital growth.

Other factors that are spurring growth in manufacturing include:

- Increased productivity

- Growing domestic production of shale oil and natural gas

- Rising wages in international markets

- American consumers embracing American-made products because they support the American job market

- The desire to protect U.S. intellectual property

The manufacturing growth seen recently can continue as the industry adapts to attract, hire and retain highly skilled workers.

What Manufacturing Needs to Thrive in the Future

According to the Brookings Institution, government buy-in is essential to propel manufacturing growth. Open trade policies and access to global markets are key. Tariff wars or overly restricted trade policies must be avoided, as nearly half of manufactured goods made in the United States were exported to countries in which the U.S. has free trade agreements.

Other recommendations the Brookings Institution makes to improve the manufacturing environment include:

- Provide financial incentives for innovation and workforce development. These can include covering education costs, tax credits for research and development, and tax credits for equipment expenses. Grants and loans for domestic manufacturers can contribute to technology innovation and business growth.

- Manufacturers must embrace technologies like artificial intelligence, automation and Big Data to keep production and product delivery quality high.

- Small firms need workforce development and technology research to create higher-paying jobs for skilled workers.

- There needs to be whistleblower protection and rules encouraging transparency in order to fight any corruption within the industry.

- Physical and digital infrastructure, including high-speed internet and roads, bridges and ports, need to be invested in to support efficient operation.

Manufacturing businesses can become involved with the National Network for Manufacturing Innovation. This organization works to strengthen American manufacturing competitiveness on a global scale, uniting manufacturers with schools, federal agencies and other organizations to drive manufacturing technology innovation. There are also grants provided by the U.S. Commerce Department’s National Institute of Standards and Technology to advance manufacturing technology.

New World Manufacturing Skills to Cultivate

Manufacturers can start talking to students early about the potential their businesses offer, at places like career fairs and in classrooms. The new world of manufacturing, according to “Manufacturing Tomorrow,” requires skills like:

- Problem-solving

- Computer and machinery knowledge

- The ability to work independently and make decisions

- Process understanding

- Science, technology, engineering and math skills

- Financial/budgetary skills

- Project management skills for manager roles

- Ability to read and develop blueprints

- Hydraulics, pneumatic and electrical systems skills

- Collaboration and communication

Today’s manufacturing employees work in tandem with robots and computer-integrated manufacturing systems. Manufacturing workers need a diverse array of industry-specific and soft skills to thrive. These should be communicated early on to young students to inspire the next generation of manufacturing professionals. Though U.S. manufacturing has become a smaller percentage of the working population than its peak in the late 1970’s, there are still many compelling reasons for today’s workers to start a career in manufacturing.

Get Help Staffing Your Manufacturing Business

At TERRA Staffing Group, we work with diverse manufacturing businesses around the country to help them with their staffing needs. We align high-quality candidates with open positions so your business can succeed.

If you’d like to learn more about hiring in manufacturing, download our free ebook, “Everything You Need to Know About Manufacturing Staffing .” Contact TERRA Staffing Group for staffing solutions that work for your industry.

If your organization needs manufacturing staffing services, we can help. At TERRA, we understand the dynamic needs and shifting demands of the manufacturing industry.

Categories: HR and Management Advice, Staffing Tips & Recruiting Trends

Tags: